|

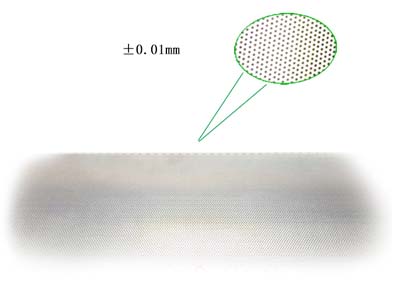

Battery collecting mesh hole

Material: kinds of special silver alloy, generally designated customers. Material: kinds of special silver alloy, generally designated customers.Precision punching diameter: The company broke through the industrial difficulties in late 2017. The limit reaches 0.27MM. And can stabilize the quality and quantity batch production. Precision hole spacing: 0.3MM (that is, 17,000 uniform fine holes in an area of 50*80mm) The above description for this product. More is to let you understand Kangding's manufacturing process. Because we are a professional non-standard custom stamping factory Constantly breaking the industry's limits, specializing in high-precision, difficult-to-precise punching and stable mass production, The electrode collecting network is an important part of the electrode and it has a very important influence on the battery performance. Lattice is often used as a lightweight skeleton for high-power zinc-silver powered batteries. Test and comparison of collector networks of different quality and structure. The larger the drift current flow cross-sectional area, the finer the mesh, the better the effect of discharge About the material: Since silver has a positive oxygen evolution potential and a more negative hydrogen evolution, it has good conductivity and stability. Moreover, no harmful impurities are introduced. Therefore, alloy punching nets with a high silver content are generally used in the industry as a current collector network. It also has sterling silver, but the cost is higher. About use: It is mainly used for high-current storage batteries. Currently, it is a battery module that is used more often. For example, new energy vehicles are most used. And other devices that require a large number of battery modules. |

|

Cell phone speaker mesh processing

|